Hydraulic Hoses in Mysore: Unveiling Key Features and Components of High-Quality Hydraulic Hoses

When it comes to fluid transmission in hydraulic systems, the significance of high-quality hydraulic hoses cannot be overstated. These hoses play a vital role in ensuring smooth and efficient operations across a wide range of applications, including construction machinery, agricultural equipment, industrial machinery, and more. Understanding their key features and components is essential for businesses in Mysore to seek reliable hydraulic hoses. In this blog, we will delve into the world of Hydraulic hoses in Mysore, exploring their crucial attributes and the factors that make them indispensable for fluid power solutions.

Understanding Hydraulic Hoses: The Backbone of Fluid Power Systems:

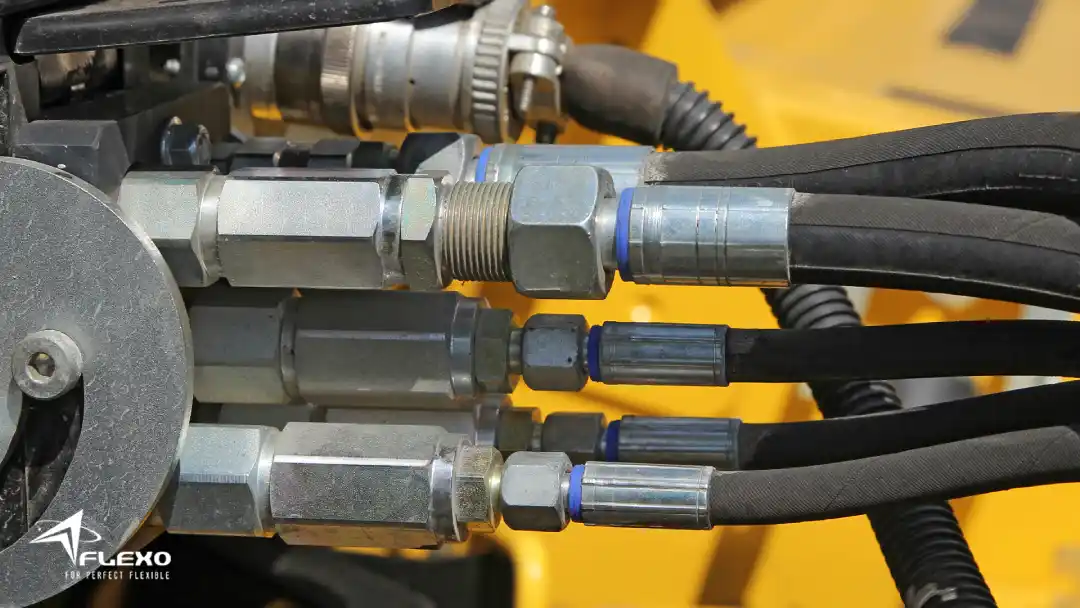

Hydraulic hoses are flexible, high-pressure tubes designed to transmit fluid within hydraulic systems. They act as a conduit for hydraulic fluid between various components, such as pumps, valves, actuators, and motors. Whether transmitting power to a hydraulic cylinder or directing hydraulic oil to control valves, these hoses are indispensable in maintaining the efficiency and safety of fluid power applications.

Key Features of High-Quality Hydraulic Hoses

- Pressure Rating: One of the primary considerations for hydraulic hoses is their pressure rating. A high-quality hydraulic hose must withstand the specific pressure levels of the hydraulic system it is intended for. Different applications may require hoses with varying pressure ratings, so choosing the right one is crucial for safe and efficient fluid power transmission.

- Temperature Resistance: Hydraulic hoses in Mysore must be designed to handle the local climate conditions, including exposure to high temperatures. Ensuring that the hoses resist temperature fluctuations is essential for preventing premature hose degradation and maintaining optimal performance.

- Flexibility and Bend Radius: Flexibility is critical, especially in applications where hoses must bend and flex during operation. The bend radius of the hose determines how tightly it can be bent without compromising its structural integrity. High-quality hoses have a suitable bend radius to prevent kinking and maintain fluid flow.

- Compatibility: Hydraulic systems often involve various hydraulic fluids with specific properties. The ideal hydraulic hose should be compatible with the fluids used in the system, ensuring that it does not degrade or react adversely to the fluid over time.

- Abrasion and Corrosion Resistance: In rugged environments or applications involving abrasive materials, hydraulic hoses must resist wear and tear. Additionally, corrosion resistance is vital for ensuring the longevity of the hoses, especially if the system operates in harsh or corrosive conditions.

- Certifications and Standards: High-quality hydraulic hoses in Mysore should meet industry-specific certifications and standards. Look for hoses that comply with ISO, SAE, or other relevant guidelines, as this ensures the hoses' quality, reliability, and safety.

Components of High-Quality Hydraulic Hoses

- Inner Tube: The inner tube is the innermost layer of the hydraulic hose and comes in direct contact with the hydraulic fluid. It is typically made from synthetic rubber or thermoplastic materials, chosen for their compatibility with the specific hydraulic fluid and their resistance to degradation. The type of inner tube material used also affects the hose's resistance to temperature, chemicals, and permeation.

- Reinforcement Layer: The hose has structural support from the reinforcing layer, which enables it to endure high pressures and avoid burst failures. Common reinforcement materials include steel wire braids or spirals, which enhance the hose's strength and durability. The number and type of reinforcement layers used depend on the hose's intended application and pressure requirements.

- Outer Cover: The outer cover protects the hose from external factors such as abrasion, chemicals, and environmental elements. It acts as a barrier that shields the inner layers from damage and extends the hose's service life. The outer cover can be made from synthetic rubber, thermoplastic, or a combination of materials, and its thickness and composition are tailored to the hose's specific use cases.

- Fittings: Hydraulic hoses in Mysore are fitted with connectors at each end to join the hose with other hydraulic components. The fittings must be securely attached to prevent leaks and maintain the integrity of the hydraulic system. Different fittings, such as straight, elbow, or tee, are available to accommodate various installation requirements.

Choosing the Right Hydraulic Hoses in Mysore

Several factors must be considered when selecting hydraulic hoses for specific applications in Mysore. The right hose should be chosen based on the system's pressure requirements, operating temperature range, environmental conditions, and fluid compatibility. Working with experienced hydraulic specialists or suppliers can help businesses in Mysore make informed decisions and ensure the proper functioning of their fluid power systems.

Benefits of High-Quality Hydraulic Hoses

Investing in high-quality hydraulic hoses brings numerous benefits to businesses in Mysore:

- Reliability: High-quality hoses are less prone to leaks, failures, and downtime, ensuring the consistent performance of hydraulic systems.

- Safety: Hydraulic systems operate under high pressure, and using subpar hoses can lead to hazardous situations. Quality hoses with proper reinforcement enhance safety and minimize the risk of accidents.

- Cost-Effectiveness: High-quality hoses may have a slightly higher upfront cost, but their extended lifespan and reduced maintenance need lead to long-term cost savings.

- Efficiency: Quality hydraulic hoses allow smoother fluid transmission, improving system efficiency and productivity.

- Reduced Environmental Impact: Durable hoses that require less frequent replacements contribute to a greener, more sustainable approach to hydraulic systems.

Regular Maintenance and Inspection

Regular maintenance and inspection are essential to maximize the lifespan and performance of hydraulic hoses in Mysore. Visual checks for signs of wear, damage, or leaks should be conducted routinely. Additionally, regular replacement of ageing hoses can prevent unexpected failures and downtime.

Conclusion

Hydraulic hoses are the lifeline of fluid power systems, enabling the efficient transmission of hydraulic fluid to various components. High-quality hydraulic hoses in Mysore are characterized by their pressure rating, temperature resistance, flexibility, compatibility, and resistance to abrasion and corrosion. Understanding these hoses' key features and components is crucial for businesses seeking reliable fluid power solutions in Mysore's diverse industries.

For premium-grade hydraulic hoses and fluid power solutions in Mysore, Flexotech Mysore is your trusted partner. Our extensive range of hydraulic hoses caters to diverse industry needs, guaranteeing optimum performance and efficiency. Contact us today to explore our comprehensive range of hydraulic hoses and fluid power components, and let us help you achieve seamless, fluid power operations.